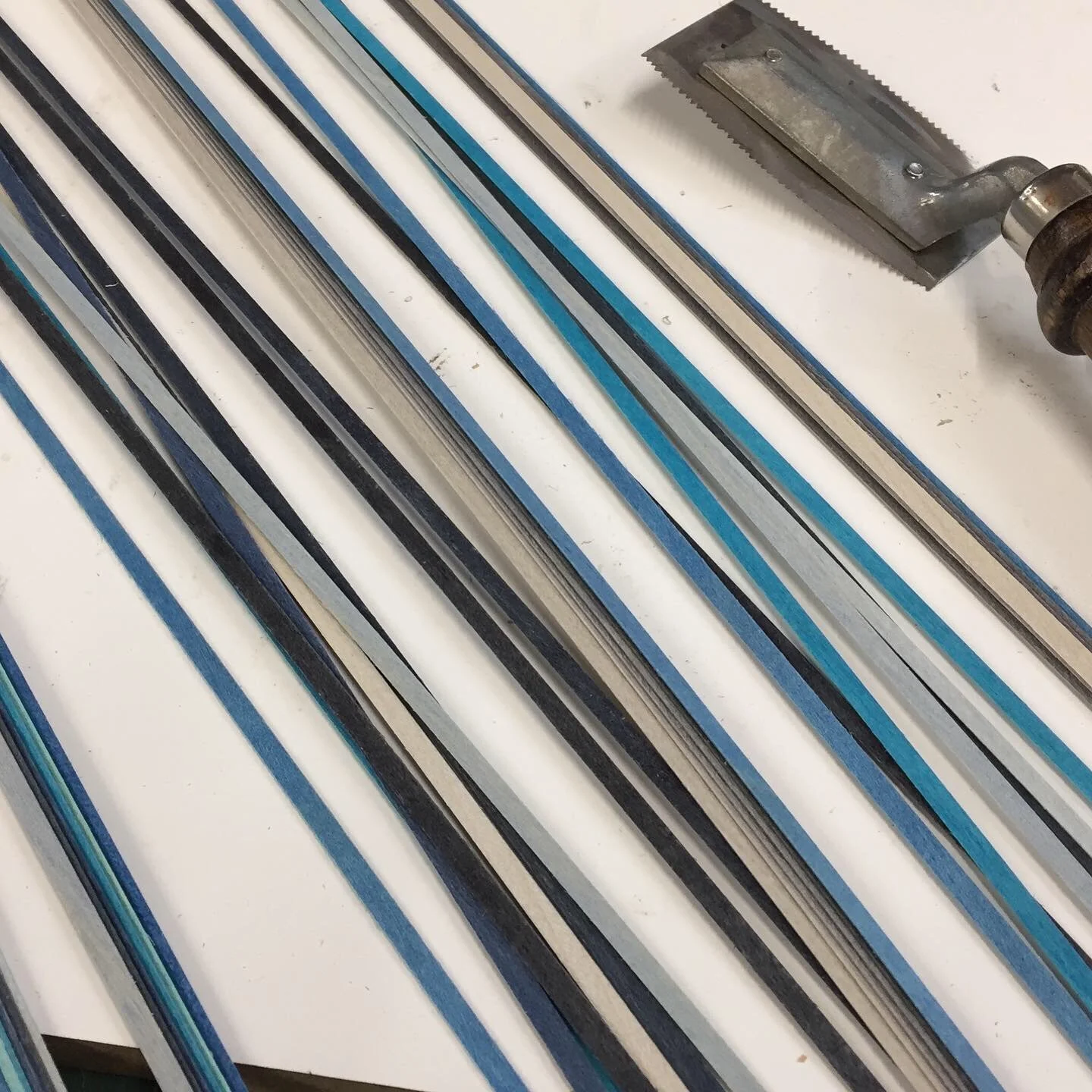

Working with thin strips of veneer

Practically all of the work I make involves using veneers in some form or other and as you may imagine at only 0.7mm thick sometimes it can be very tricky to get the veneers to do what you want… The problem becomes even more acute when working with veneer strips that are only 3mm or 4mm wide!

There are two main problems, first the veneers want to bend, twist and expand as soon as they are cut or are moistened from the glue and secondly, any inaccuracy in cutting the strips is magnified across the design as it is built up - a difference of 0.1mm becomes 1mm by the time 10 strips are joined together, enough to ruin a delicate design.

There’s only one answer and that’s to cut the strips very, very carefully so that they are all the same size and to edge glue them after they’ve been joined so that they behave in the same way as a single sheet of veneer would do.

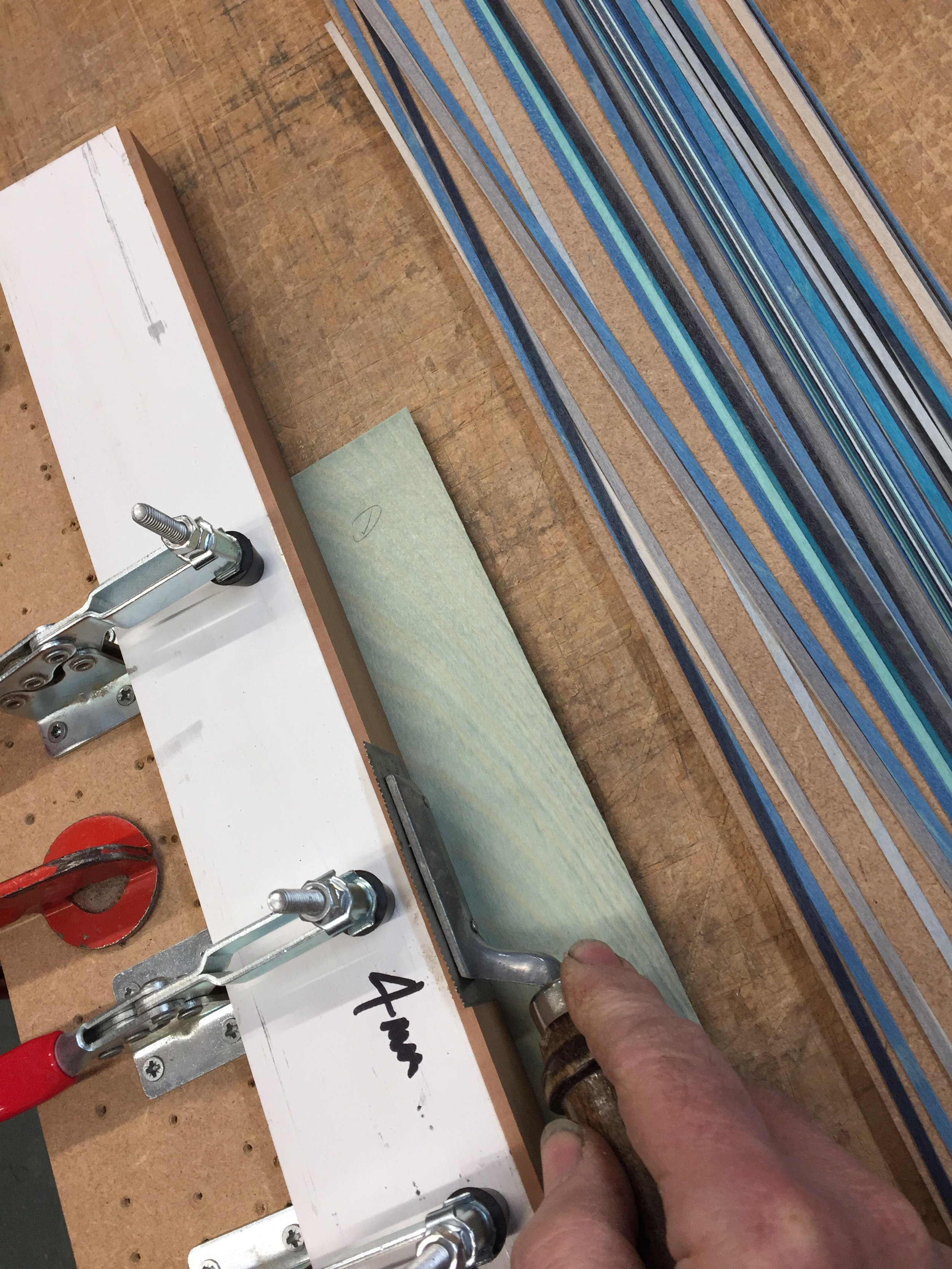

I use a very sharp veneer saw which has tiny teeth and no kerf to make the cuts, with the veneers taped together in a pack and held firmly in a home-made jig. It’s very time consuming but it does the job and allows me to create designs such as the candy stripe mirrors and the pinstripe boxes.